Apr

8th

Stay connected Subscribe to our RSS feed

What is fuel injection?

Fuel injection is what makes vehicles go. How? By spraying fuel and mixing it up with air, said mixture gets compressed and ignites (courtesy of the spark plugs), pushing the piston back down and engaging the crankshaft which, in turn, engages the drive shaft that connects the driving axles.

There are two different ways to achieve this momentum: multi-port injection or direct injection. The latter can be found in Ford's EcoBoost engines and Mazda's SKYACTIV engines, for instance. It's widely acclaimed for maximizing combustion efficiency and fuel economy while reducing emissions in the process.

What are the main differences? What motivated engineers to develop direct injection technology? Let's see...

Carburetors

Older engines used carburetors to create the aforementioned air-fuel mixture. It all worked mechanically, with a butterfly valve controlling the air flow through the carburetor and orifices (referred to as “jets”) distributing the fuel from the intake manifold to the cylinders. Injection timing lacked precision and, consequently, the amount of unburnt fuel was significant.

Electronic injection

Since the 1980s, the quest for more precise systems has led engineers to replace carburetors with electronically controlled fuel injectors. Soon enough, automobiles transformed into mobile computers.

It was a big step forward, but equally big ones could still be made. The reason is simple: Cylinders operate alternatively, not simultaneously. Engineers used an average to send fuel to all cylinders at the same time. As a result, fuel often got trapped until the intake valves opened up, which led to poor fuel atomization. Instead of fine particles, that fuel returned to liquid form as it touched the walls of the intake manifold. It could not blend perfectly with air, and therefore went to waste as unburnt fuel.

Multi-point injection

In order to achieve optimum combustion, fuel injection needs to happen as close to the combustion chamber as possible. Engineers decided to give each cylinder a dedicated injector, a setup that's now known as multi-point fuel injection and allows precise fuel metering. By shortening the fuel flow, atomized fuel is less likely to return to liquid form.

Most modern cars like the Toyota Corolla, Honda Civic and Subaru Impreza rely on multi-point injection.

However, since the fuel injectors are still outside the cylinders, those engines are unable to burn every single drop of fuel. Unburnt fuel creates pollution in the exhaust system, meaning that the catalytic converter needs to be at the top of its game.

Direct injection

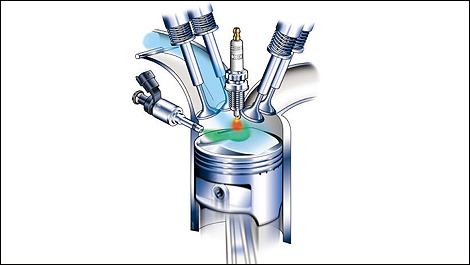

Some smart and crafty folks came up with the idea to inject fuel directly into the cylinders (as opposed to the intake manifold). We see it a lot with diesel engines, like Volkswagen's. For more precise injection timing, fuel is pressurized at a whopping 1,500 pounds per square inch (PSI) instead of just 50. And that goes for turbo engines, too, which already rely on compressed air. The result is more effective ignition and combustion.

The most sophisticated injectors are amazingly precise, up to a single millisecond, even at 7,000 rpm.

Direct injection considerably reduces the amount of greenhouse gases vehicles release into the environment. With increasingly strict emission standards, this technology looks to be the way of the future for internal combustion engines.

Fuel injection is what makes vehicles go. How? By spraying fuel and mixing it up with air, said mixture gets compressed and ignites (courtesy of the spark plugs), pushing the piston back down and engaging the crankshaft which, in turn, engages the drive shaft that connects the driving axles.

There are two different ways to achieve this momentum: multi-port injection or direct injection. The latter can be found in Ford's EcoBoost engines and Mazda's SKYACTIV engines, for instance. It's widely acclaimed for maximizing combustion efficiency and fuel economy while reducing emissions in the process.

What are the main differences? What motivated engineers to develop direct injection technology? Let's see...

|

| Direct injection (Illustration: Ford) |

Carburetors

Older engines used carburetors to create the aforementioned air-fuel mixture. It all worked mechanically, with a butterfly valve controlling the air flow through the carburetor and orifices (referred to as “jets”) distributing the fuel from the intake manifold to the cylinders. Injection timing lacked precision and, consequently, the amount of unburnt fuel was significant.

Electronic injection

Since the 1980s, the quest for more precise systems has led engineers to replace carburetors with electronically controlled fuel injectors. Soon enough, automobiles transformed into mobile computers.

It was a big step forward, but equally big ones could still be made. The reason is simple: Cylinders operate alternatively, not simultaneously. Engineers used an average to send fuel to all cylinders at the same time. As a result, fuel often got trapped until the intake valves opened up, which led to poor fuel atomization. Instead of fine particles, that fuel returned to liquid form as it touched the walls of the intake manifold. It could not blend perfectly with air, and therefore went to waste as unburnt fuel.

Multi-point injection

In order to achieve optimum combustion, fuel injection needs to happen as close to the combustion chamber as possible. Engineers decided to give each cylinder a dedicated injector, a setup that's now known as multi-point fuel injection and allows precise fuel metering. By shortening the fuel flow, atomized fuel is less likely to return to liquid form.

Most modern cars like the Toyota Corolla, Honda Civic and Subaru Impreza rely on multi-point injection.

However, since the fuel injectors are still outside the cylinders, those engines are unable to burn every single drop of fuel. Unburnt fuel creates pollution in the exhaust system, meaning that the catalytic converter needs to be at the top of its game.

Direct injection

Some smart and crafty folks came up with the idea to inject fuel directly into the cylinders (as opposed to the intake manifold). We see it a lot with diesel engines, like Volkswagen's. For more precise injection timing, fuel is pressurized at a whopping 1,500 pounds per square inch (PSI) instead of just 50. And that goes for turbo engines, too, which already rely on compressed air. The result is more effective ignition and combustion.

The most sophisticated injectors are amazingly precise, up to a single millisecond, even at 7,000 rpm.

Direct injection considerably reduces the amount of greenhouse gases vehicles release into the environment. With increasingly strict emission standards, this technology looks to be the way of the future for internal combustion engines.

The latest auto news, reviews, prices, product and vehicle releases.

The latest auto news, reviews, prices, product and vehicle releases.