Jul

10th

Stay connected Subscribe to our RSS feed

Auto123.com had the unique opportunity to spend some time with members of the Renault Sport F1 Team to experience the thrill of starting a V8 Formula 1 engine.

Just a quick reminder: All F1 engines must be normally aspirated, 2.4L, 90-degree V8s that can rev up to a maximum of 18,000 rpm. Power figures are not released by the manufacturers, but it is estimated to be around 800 horsepower.

Unlike our everyday road cars, an F1 engine cannot be started from cold due to the very tight bearing and piston-to-bore clearances.

Step 1 - Warming up the engine block

“We start by warming the engine up to a temperature of 80°C by circulating hot coolant through the engine and radiators,” says Henry Saint-Michel, engine technician at Renault Sport F1, who is responsible for Kimi Raikkonen's car at Lotus F1 Team.

“We then add compressed air in the bottle located inside the sidepod. This compressed air is used to counterbalance any leak the pneumatic valve system may suffer from,” he adds. “We also check the oil level and temperature. At this moment, there's almost no oil in the engine; it's mostly located inside the oil tank.”

The engine ECU is connected to the laptop computer of the technician. Various sensors for position, temperature and pressure send data to the laptop.

Step 2 - Building up oil pressure

Once the temperature of the engine has reached 80 degrees, the hoses from the heating system are disconnected.

The next step is to crank the engine without firing it. “Using the electric starter, we crank the motor so the oil circulates through the galleries to ensure that the pistons, rings, bearings, con rods, and other internal components are covered with a thin film of oil,” Saint-Michel explains.

To prevent the engine from firing, Saint-Michel holds down a red button located on his work desk. A Lotus mechanic cranks the engine with the electric starter.

“On the screen, I see the oil pressure building up and the engine getting ready,” he continues. “When all systems are go, I tell the mechanic who works the starter to fire up the engine. By releasing the red button, I allow the starter to fire up the V8.”

The engine comes to life and idles at approximately 3,000-4,000 rpm. The water temperature immediately drops to 60°C (due to water circulating through the cooling system) but it quickly climbs back to 80°C at a rate of about one degree per two seconds.

Saint-Michel can rev the engine using the joystick, called the “pit pedal.”

“The Lotus guy in charge of electronics then runs a fully automated warm-up software program. Another mechanic, sitting in the driver's seat, changes gears, engages the clutch, and turns the steering wheel from left to right to bleed the power assist circuit,” he tells us. “Once this is done, he gives me back control of the procedure. I rev the engine up to 7,000 rpm for 5-7 seconds before stopping it. This is to ensure that the engine is fully scavenged of oil, with the maximum possible amount of oil returned to the tank. We then perform an accurate check of the oil level.”

The engine remains at its operating temperature all day long since the car is taken to the track on a regular basis. If necessary, a short fire-up may be carried out to warm the engine in order to keep it at the correct temperature.

In Part 2, we are going to start the engine ourselves!

Just a quick reminder: All F1 engines must be normally aspirated, 2.4L, 90-degree V8s that can rev up to a maximum of 18,000 rpm. Power figures are not released by the manufacturers, but it is estimated to be around 800 horsepower.

Unlike our everyday road cars, an F1 engine cannot be started from cold due to the very tight bearing and piston-to-bore clearances.

|

| The heating unit can be seen on the left, sitting on the floor. (Photo: René Fagnan) |

Step 1 - Warming up the engine block

“We start by warming the engine up to a temperature of 80°C by circulating hot coolant through the engine and radiators,” says Henry Saint-Michel, engine technician at Renault Sport F1, who is responsible for Kimi Raikkonen's car at Lotus F1 Team.

“We then add compressed air in the bottle located inside the sidepod. This compressed air is used to counterbalance any leak the pneumatic valve system may suffer from,” he adds. “We also check the oil level and temperature. At this moment, there's almost no oil in the engine; it's mostly located inside the oil tank.”

The engine ECU is connected to the laptop computer of the technician. Various sensors for position, temperature and pressure send data to the laptop.

|

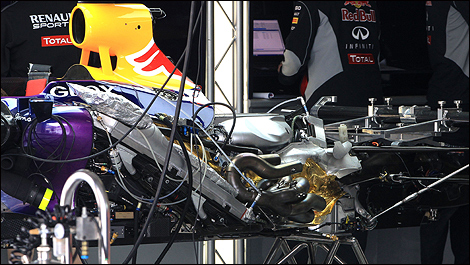

| The Renault engine bolted to the Red Bull chassis. (Photo: WRI2) |

Step 2 - Building up oil pressure

Once the temperature of the engine has reached 80 degrees, the hoses from the heating system are disconnected.

The next step is to crank the engine without firing it. “Using the electric starter, we crank the motor so the oil circulates through the galleries to ensure that the pistons, rings, bearings, con rods, and other internal components are covered with a thin film of oil,” Saint-Michel explains.

To prevent the engine from firing, Saint-Michel holds down a red button located on his work desk. A Lotus mechanic cranks the engine with the electric starter.

“On the screen, I see the oil pressure building up and the engine getting ready,” he continues. “When all systems are go, I tell the mechanic who works the starter to fire up the engine. By releasing the red button, I allow the starter to fire up the V8.”

The engine comes to life and idles at approximately 3,000-4,000 rpm. The water temperature immediately drops to 60°C (due to water circulating through the cooling system) but it quickly climbs back to 80°C at a rate of about one degree per two seconds.

Saint-Michel can rev the engine using the joystick, called the “pit pedal.”

|

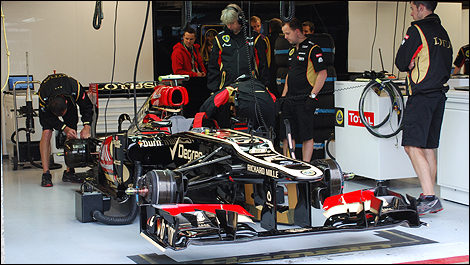

| Kimi Raikkonen's Lotus in the garage. The electric starter can be seen on the far left. (Photo: René Fagnan) |

“The Lotus guy in charge of electronics then runs a fully automated warm-up software program. Another mechanic, sitting in the driver's seat, changes gears, engages the clutch, and turns the steering wheel from left to right to bleed the power assist circuit,” he tells us. “Once this is done, he gives me back control of the procedure. I rev the engine up to 7,000 rpm for 5-7 seconds before stopping it. This is to ensure that the engine is fully scavenged of oil, with the maximum possible amount of oil returned to the tank. We then perform an accurate check of the oil level.”

The engine remains at its operating temperature all day long since the car is taken to the track on a regular basis. If necessary, a short fire-up may be carried out to warm the engine in order to keep it at the correct temperature.

In Part 2, we are going to start the engine ourselves!

The latest auto news, reviews, prices, product and vehicle releases.

The latest auto news, reviews, prices, product and vehicle releases.